Product introduction

The hydraulic pile breaker is also called the hydraulic pile cutter. The construction of modern buildings requires foundation piling. In order to better connect the foundation piles with the ground concrete structure, the foundation piles generally extend out of the ground by 1 to 2 meters, so that the steel bars are completely preserved. On the ground, artificial air pick crushers are generally used for crushing, which is not only slow in efficiency but also high in cost.

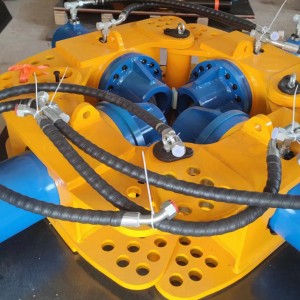

Through continuous research and development experiments by Sinovogroup, the brand-new SPA series hydraulic pile breaker has been launched. The SPA series hydraulic pile breaker provides pressure to multiple oil cylinders of the pile breaker through the power source. Pile head cut off. During the construction of the pile breaker, the hydraulic pile breaker has the advantages of simple operation, high construction efficiency, low noise and low cost, and is suitable for pile group construction projects. SPA series hydraulic pile breaker adopts a highly modular combination. Through the pin-shaft connection module, it can be combined with different modules to cut off the diameter of the pile head within a certain range, including the square pile and the round pile.

Most of the traditional pile head breaking methods use methods such as hammer blowing, manual drilling or air pick removal; however, these traditional methods have many disadvantages such as shock damage to the internal structure of the pile head, and now hydraulic concrete pile breakers have been It is a new, fast and efficient concrete structure demolition tool invented by combining the advantages of the above-mentioned various demolition equipment and the characteristics of the concrete structure itself. Greatly reduce the labor intensity of workers and improve work efficiency. Combined with the demolition method of the concrete pile breaker, it takes only a few minutes to cut off a pile head.

SPA series hydraulic pile breaker will not generate pressure wave, no vibration, noise and dust, and will not damage the pile foundation when breaking concrete piles. The machine has many advantages such as safety, high efficiency and energy saving in the field of concrete pile removal. With modular design, each module has a separate oil cylinder and drill rod, and the oil cylinder drives the drill rod to achieve linear motion. Multiple modules are combined to adapt to the construction of different pile diameters, and are connected in parallel through hydraulic pipelines to achieve synchronous action. The pile body is squeezed at multiple points on the same section at the same time, and the pile body at this section is broken.

SPA8 Pile Breaker Construction’s Parameters

|

Module numbers |

The diameter range (mm) |

Platform weight(t) |

Total pile breaker weight(kg) |

Height of single crush pile(mm) |

|

6 |

450-650 |

20 |

2515 |

300 |

|

7 |

600-850 |

22 |

2930 |

300 |

|

8 |

800-1050 |

26 |

3345 |

300 |

|

9 |

1000-1250 |

27 |

3760 |

300 |

|

10 |

1200-1450 |

30 |

4175 |

300 |

|

11 |

1400-1650 |

32.5 |

4590 |

300 |

|

12 |

1600-1850 |

35 |

5005 |

300 |

|

13 |

1800-2000 |

36 |

5420 |

300 |

Specification (a group of 13 modules)

|

Model |

SPA8 |

|

Range of Pile diameter (mm) |

Ф1800-Ф2000 |

|

Maximum Drill rod pressure |

790kN |

|

Maximum stroke of hydraulic cylinder |

230mm |

|

Maximum pressure of hydraulic cylinder |

31.5MPa |

|

Maximum flow of single cylinder |

25L/min |

|

Cut the number of pile/8h |

30-100 pcs |

|

Height for cutting pile each time |

≦300mm |

|

Supporting the digging machine Tonnage (excavator) |

≧36t |

|

One-piece module weight |

410kg |

|

One-piece module size |

930x840x450mm |

|

Work status dimensions |

Ф3700x450 |

|

Total pile breaker weight |

5.5t |