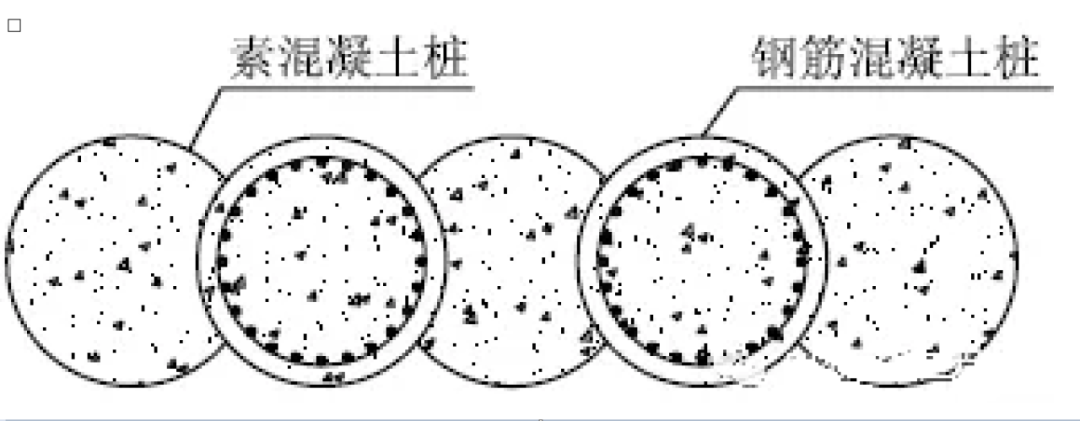

The secant pile wall is a form of pile enclosure of foundation pit. The reinforced concrete pile and plain concrete pile are cut and occluded, and Piles are arranged to form a wall of piles interlocking with each other. The shear force can be transferred between the pile and pile to a certain extent, and while retaining earth, it can effectively play the role of stopping water, and is suitable for use in areas with high groundwater level and narrow site.

Design of secant pile wall

In theory, because the adjacent plain concrete pile and reinforced concrete pile interlock to form the wall, the plain concrete pile and reinforced concrete pile play a joint effect when the pile wall is stressed and deformed. For reinforced concrete pile, the existence of plain concrete pile increases its flexural stiffness, which can be considered by equivalent stiffness method in calculation when experienced.

However, the study of a practical project shows that the contribution rate to the stiffness of the plain concrete pile is only about 15% with the appearance of cracks at the bottom of the excavation. Therefore, when the bending moment is large, the stiffness of plain concrete pile can not be considered; When the bending moment is small, the stiffness contribution of the plain concrete pile can be properly considered when calculating the deformation of the pile row, and the stiffness of the reinforced concrete pile can be multiplied by the stiffness improvement coefficient of 1.1~1.2.

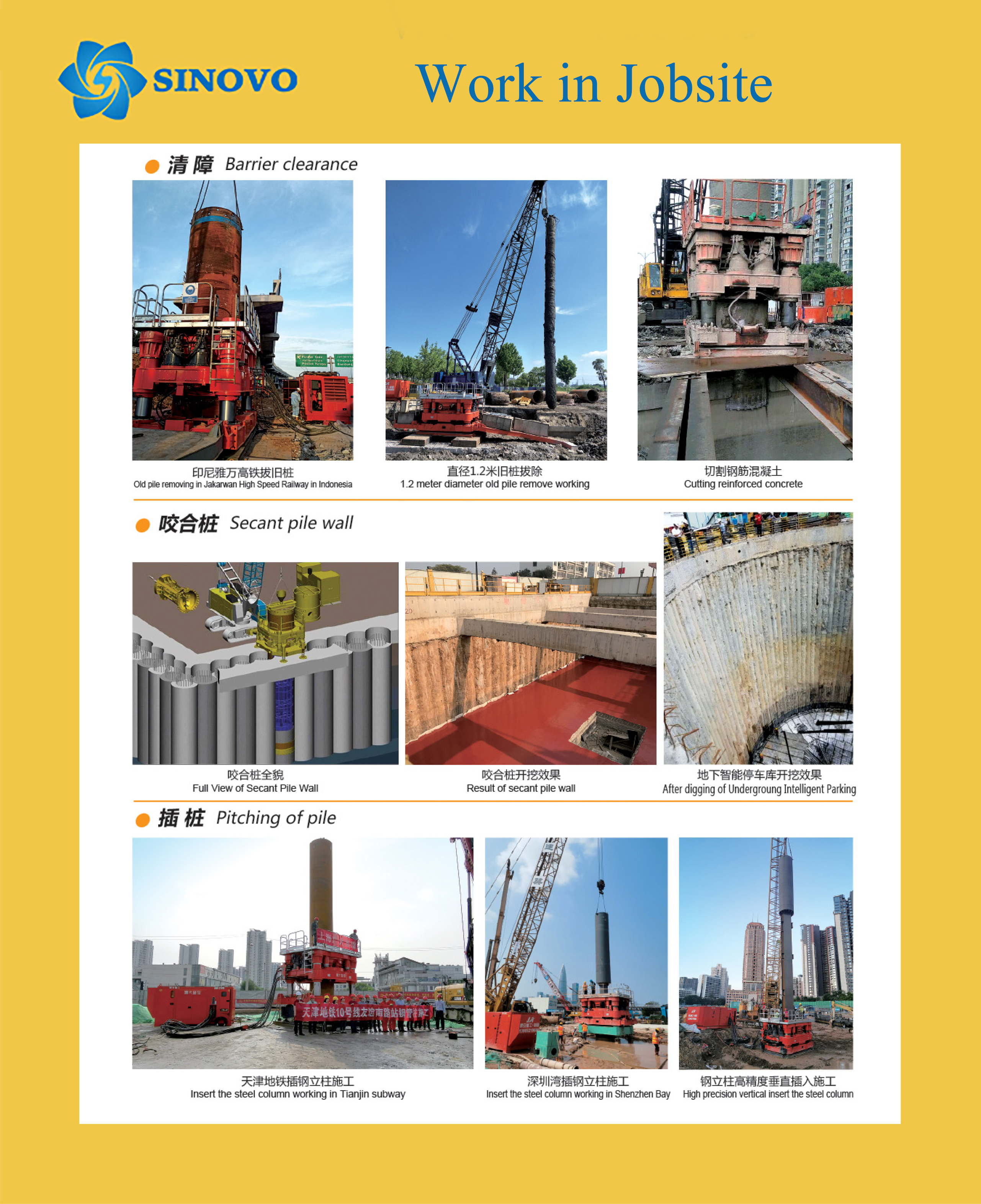

Construction of secant pile wall

The plain pile is cast with super retarded concrete in advance. The concrete intersecting part of the adjacent plain concrete piles is cut by the cutting ability of the casing drill before the initial setting of the plain concrete piles, and then the meat piles are poured to realize the occlusion of the adjacent piles.

The construction process of single secant pile wall is as follows :

(a) Guard drill in place: When the positioning guide wall has sufficient strength, use the crane to move the drill in place, and make the center of the main host pipe holder position in the center of the guide wall hole.

(b) Single pile hole formation: With the pressing of the first section of the protective cylinder (depth of 1.5m ~ 2.5m), the arc bucket takes soil from the protective cylinder, grabs the soil while continuing to press down until the first section is fully pressed in (generally leaving 1m ~ 2m on the ground to facilitate the connection of the cylinder) to detect the verticality. After passing the test, the second protective cylinder is connected, and so on the cycle until the pressure reaches the design pile bottom elevation.

(c) Lifting the steel cage: For pile B, the reinforcement cage should be placed after the hole inspection is qualified. At this time, the reinforcement cage elevation should be correct.

(d) concrete injection: If there is water in the hole, it is necessary to use underwater concrete injection method; If there is no water in the hole, use the dry hole perfusion method and pay attention to vibration.

(e) Drum pulling into pile: while pouring concrete, pull out the protection cylinder, and pay attention to keeping the bottom of the protection drum ≥2.5m below the concrete surface.

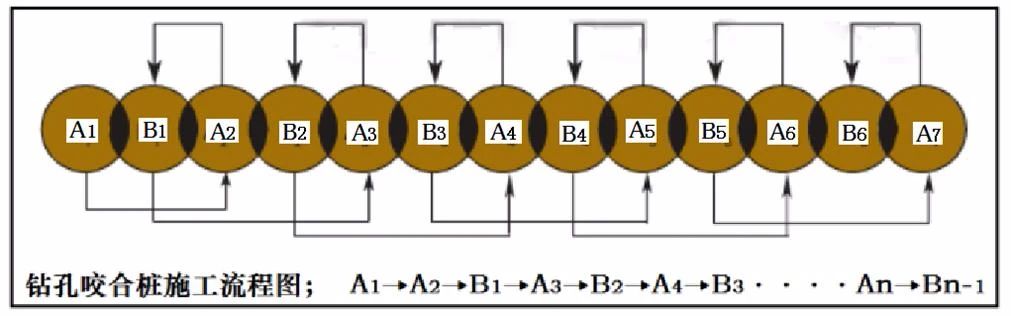

Pile row construction process is as follows:

For a row of occluding piles, the construction process is A1→A2→B1→A3→B2→A4→B3, and so on.

Concrete key indicators:

The determination of concrete retarding time of pile A needs to calculate the concrete retarding time of pile A according to the following formula after determining the time t required for single pile formation of piles A and B:

T=3t+K

Formula: K — reserve time, generally 1.5t.

In the process of hole formation of pile B, because the concrete of pile A is not completely solidified and is still in A flowing state, it may rush into the hole of pile B from the intersection of pile A and pile B, forming a “pipe surge”. The overcoming measures are:

(a) Control the concrete slump of pile A <14cm.

(b) The casing shall be inserted at least 1.5m below the bottom of the hole.

(c) Observe whether the concrete top surface of pile A sinks in real time. If subsidence is found, the excavation of pile B should be stopped immediately and while pressing down the protection cylinder as much as possible, fill the soil or water into pile B (balance the concrete pressure of pile A) until the “pipe surge” is stopped.

Other measures:

When encountering underground obstacles, because the secant pile wall adopts steel casing, the operator can lift down the hole to remove obstacles when it is determined that the environment is safe,.

It is possible to take up the placed steel cage when pulling out the pile casing upward. Preventive measures can be selected to reduce the particle size of the concrete aggregate of post B or a thin steel plate slightly smaller than itself can be welded to the bottom of the steel cage to increase its anti-floating ability.

During the construction of the secant pile wall, we should not only consider the slow setting time control of the plain concrete pile, pay attention to the construction time arrangement of the adjacent plain concrete and reinforced concrete pile, but also control the vertical degree of the pile, so as to prevent the reinforced concrete pile from being unable to be constructed due to the excessive growth of the strength of the concrete pile. Or because the completed plain concrete pile perpendicularity deviation is large, resulting the situation of poor bonding effect with reinforced concrete pile, even the foundation pit leakage, can not stop water and failure. Therefore, reasonable arrangements should be made for the construction of the secant pile wall, and construction records should be made to facilitate the smooth construction. In order to control the hole forming accuracy of the occluding pile to meet the requirements of design and related specifications, the whole process control of hole forming accuracy should be adopted. Two line columns can be hung on the pile forming machine to control the perpendicularity of the outer wall of the south-north and east-west protection cylinder and two clinometer can be used to check the perpendicularity of the hole. Correction and adjustment should be made in time when deviation is found.

Similar to the construction of underground continuous wall, for the construction of fully casing secant pile wall, it is also necessary to make a guide wall before drilling into pile, which has satisfied the control of the plane position of the drilled occlusive pile and served as a platform for the construction machinery to prevent the hole collapse, make sure the pile casing of secant pile wall is upright, and ensure the smooth operation of the fully casing drill. The construction requirements of the guide wall can be seen in the relevant requirements of the underground diaphragm wall.

Post time: Nov-17-2023